AET (HK) LIMITED Service Offering

Supply Chain Development, Management & Optimization

● Supplier Development & Management

● Product Development & Sourcing

● Project Management

Supplier Quality Management

Quality Management System (QMS) Consulting

● QMS Setup according to ISO9001 or IATF16949

● Continuous quality improvement

Quality Management System (QMS) Audit

● Focuses on the development, documentation and implementation of the organization-wide QMS to determine its compliance with corporate policies, contractual obligations and regulatory requirements.

● Covers the supplier’s general QMS, production processes & products

● Includes full documentation and on-site audits

● Follows with consulting, coaching, monitoring & verification for nonconformities (NC) corrections & continuous improvements.

Process / Control Plan Audit

● Focuses on specific processes designed for the Client’s products

● Typically based on factory’s Control Plan, so also called Control Plan Audit

Product Audit

● Focuses on specific products the client is purchasing

Factory Inspection

● Simplified QMS Audit to provide an efficient and cost-effective tool for international buyers to assess a factory’s basic capability in supplying quality goods so the buyers can make sound purchasing decisions.

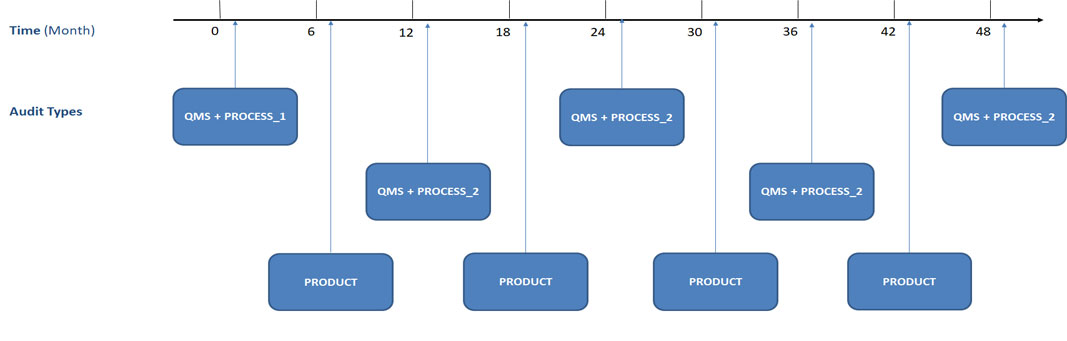

Recommended Audit Types & Cycles:

Remark: PROCESS_1 = Process Audit relating to products covered by the factory’s certification

PROCESS_2 = Process Audit relating to products the client is purchasing

PRODUCT = Product Audit that focuses on products the client is purchasing

Services to OEMs Clients

AET (HK) LIMITED has been assisting international automotive OE customers in the development, management and optimization of their China supply chains for over 2 decades.

When international OE clients want to develop products in China, AET (HK) LIMITED supports the clients in supplier qualification and selection, management of product development, procurement process management and supplier quality management.

Working closely with the clients, AET (HK) LIMITED would monitor, coordinate, and manage the entire process according to the clients’ requirements and instructions.

Supplier qualification & selection:

● Receiving RFQ from the client (with detailed information, including 2D & 3D drawings, specifications, volume, project timeline, etc.)

● Research for potential suppliers from existing supplier database as well as cultivating new suppliers based on the client’s requirements (Long List)

● Initial benchmark

● Pre-auditing by AET (HK) LIMITED based on IATF 16949 using AET (HK) LIMITED’s internal audit reporting format (Short List)

● Official inspection & auditing by the client based on the client’s audit reporting format, to be assisted by AET (HK) LIMITED

● Selection of supplier(s) based on audit results, requesting for corrections of non-conformities discovered during audit and quality improvement

● Supply Contract negotiation on behalf of the client

Management of product development project:

● 3D rough/raw part design and approval

● Tooling design and development

● Tooling trial (through manufacturing – samples/drawing/testing report submission)

● Sample validation

Procurement process management

● Purchase order management

● Production status monitoring

● Delivery & logistic coordination

● Shipping documents verifications:

∗ Invoice

∗ BL

∗ Pre-shipment Inspection Report

∗ Test Report

Supplier quality management

●Quality performance monitoring

● Annual audits

Quality complaints/warranty claims handling

● Customer report

● Factory feedback

● Technical support

● 8D Report

AET (HK) LIMITED’s Value-additions to Clients

Reducing the overall costs of procurement operations

●Lower product & production costs

●Reduced costs of labor and travelling by European staff

Minimizing costs from potential quality risks

●Catch potential quality issues earlier

●Continuous quality improvement